How To Repair A Subwoofer Voice Coil

Subwoofer Voice scroll repair

Many people enjoy loud music. They damaged their subwoofer because loud music requires more than power. If yous overpower the coil, you will ordinarily impairment it. When the vocalization curlicue is damaged, The subwoofer does not produce sound, or you hear the sound, simply with distortion.

Voice coils differ between dissimilar subwoofers. Sometimes you can buy vox coils from the market, just sometimes you lot can't. Today, nosotros volition hash out how to repair subwoofer voice coil by hand. We demonstrate a stride-by-step guide on How to set a blown subwoofers' voice coils in the following guide. Let'due south get directly into it.

Required Equipment

- Insulated copper wire

- Toluene

- Yellow Contact Adhesive

- Ho-hum-drying epoxy resin

- Scissor

- Masking Tape

- Sparse wooden sticks

- 10-ray's plastic film

- A clean material

- A piece of aluminum foil

- Kraft paper

- Tip spear scalpel

- Estrus Gun

- Mold with the same diameter every bit your voice coil.

- Winding Machine

Steps to Follow

Step i: It is first necessary to position the mold in the winding auto and tightly tighten it.

Stride two: Measure the width of the damaged voice coil.

Step 3: You should measure out the aluminum strip face over with a tolerance of 2 millimeters.

Step four: Using a pencil or screwdriver, curve the aluminum strip. You must face the silver side inward when you make your band.

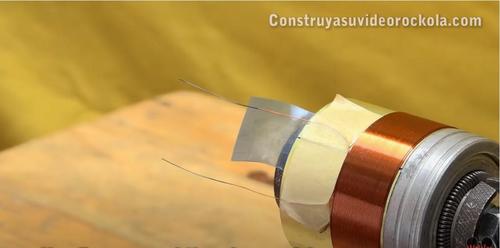

Step 5: Once the mold has been placed, the aluminum strip is wrapped around it and taped downwards. After the mold is placed, Wrap the aluminum strip around it and tape it down.

Step vi: On the lesser of the aluminum, place both x-ray strips. Strips of X-ray paper make it easier to remove the aluminum from the mold.

Step 7: Now newspaper the epoxy resin. You need to use equal parts and mix them well with thin wooden sticks. Information technology is too a expert idea to add epoxy solvent if you will not be using toluene. Remix it again if necessary.

Step viii: As soon as you reach the top of the masking tape, pull downward the copper wire.

Step 9: We utilise epoxy resin over the unabridged top of the aluminum when we whorl upwardly the wire.

Footstep 10: Later you've wound the wire, it'southward time to crimp it. Make sure that the start turnaround finishes at the wire's beginning point. The machine should be started subsequently the start plough is completed, and the wire turns should be rolled upwards without leaving any infinite between them and without that turn mounted on another turn. It should be perfect winding.

Pace 11: Apply the epoxy resin over the copper winding after yous ringlet upwards the get-go winding wire layer.

Step 12: Once the epoxy resin is practical over the copper winding, turn the wire over the first layer of winding again. Retrieve to wind the second layer wire the aforementioned fashion nosotros wound the first layer wire. With masking record, we secured the 2nd layer and with a wire cutter, we cutting the same length wire every bit the starting wire with the assist of a cutter or scissors.

Step 13: You tin now leave it to dry for 24 hours or you lot tin can use a heat gun to dry it. Remove the bubbles with a material as wire and resin are heated with the heat gun.

Footstep 14: Must remove varnish from wire ends with a lighter.

Stride 15: Sanded the wire with sandpaper now.

Step 16: The beginning wire is the positive and the end wire is the negative.

Pace 17: Now y'all can likewise bank check the positive and negative through a digital voltmeter.

Footstep xviii: Remove the ten-ray strips from the bottom of the aluminum strips at present. Now nosotros need to remove the voice coil very carefully from the mold.

Stride 19: Measure out the width of the voice coil collar now.

Pace 20: Now we apply the yellowish agglutinative contact beyond the surface of the vocalisation roll collar and dry information technology for a while.

Step 21: Also utilise the yellow agglutinative contact on kraft paper. After the glue has dried, we identify the kraft paper on the collar of the vocalism coil. After going around nosotros put the wires over the paper. Apply some yellow adhesive contact on the wire and place the kraft paper and let it dry. Besides, make sure that they are isolated.

Step 22: And then use a textile moistened with toluene to make clean the remaining glue.

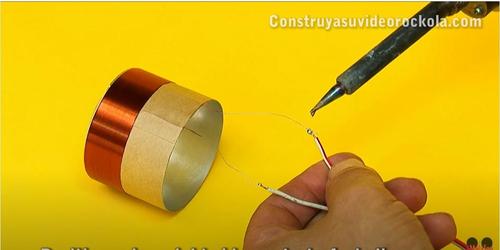

Pace 23: Now use the solder paste to the terminate of the scroll wire and weld them.

Pace 24: You lot need to make sure that the voice coil is matching the speaker.

Pace 25: Now yous demand to connect the positive wire to positive and the negative to negative. (stating of winding is positive and ending of winding is negative)

Step 26: If yous want to check that the wires you connect are right then utilize a battery or cell and connect positive to positive stop and negative to negative stop. If the vox roll moves upward then y'all connect the right wires.

Step 27: Now your voice coil is set up, and yous can supervene upon the voice coil.

Step 28: Reassemble and Ready Other Parts as you remove them.

Enjoy your music and subwoofer now. If you still have trouble following these steps on how to repair a subwoofer voice curl or if you don't understand them, you might detect this video useful.

Hi, this is Ali. I accept been an enthusiast of speakers especially subwoofers. So, I am finally going to throw my feel out for you lot guys.

Source: https://subwoofermag.com/how-to-repair-subwoofer-voice-coil/

Posted by: baisdenbefer1961.blogspot.com

0 Response to "How To Repair A Subwoofer Voice Coil"

Post a Comment